Meticulously Engineered, Top-Tier Gas Carburizing Furnaces

A gas carburizing furnace is used in a metal heat treatment process called carburizing.

It is a case hardening process that increases the carbon content at the surface layer of a low-carbon steel workpiece. Gas carburizing is widely used in industries such as automotive, aerospace, and tool manufacturing to improve wear resistance, fatigue strength, and overall mechanical properties of steel components.

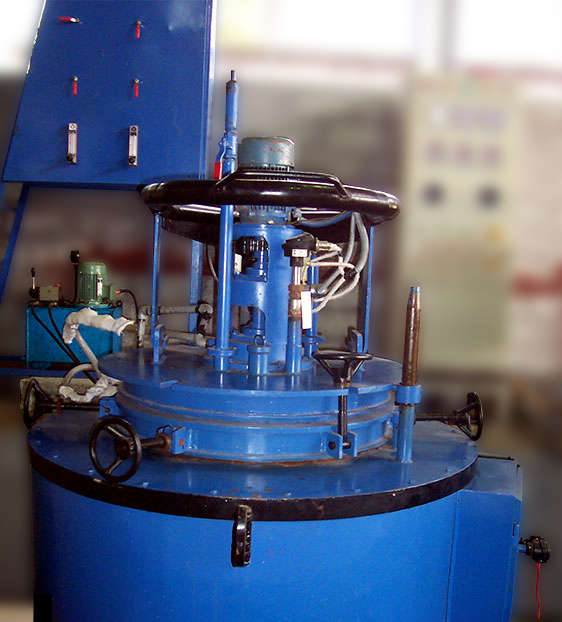

Vibrant Thermal Engineering offers these furnaces in various configurations, such as batch furnaces, continuous furnaces, and pit furnaces to suit different industrial needs.

Built by top Gas Carburizing Furnace Manufacturers in India, this furnace consists of a sealed chamber where the metal parts are placed. The chamber is filled with a carbon-rich gas atmosphere, commonly a mixture of hydrocarbons such as methane or propane. The heat causes the carbon atoms from the gas to diffuse into the surface of the steel, creating a hardened surface layer while maintaining a softer core.

Vibrant Thermal Engineering offers these furnaces in various configurations, such as batch furnaces, continuous furnaces, and pit furnaces to suit different industrial needs.

Built by top Gas Carburizing Furnace Manufacturers in India, this furnace consists of a sealed chamber where the metal parts are placed. The chamber is filled with a carbon-rich gas atmosphere, commonly a mixture of hydrocarbons such as methane or propane. The heat causes the carbon atoms from the gas to diffuse into the surface of the steel, creating a hardened surface layer while maintaining a softer core.