Technical Specifications

1. Insulation

- Brick Fibre Module & Board

2. Chamber Design

- Cylindrical/Rectangular

3. Temperature Range

-

500°C to 700°C

(for Aluminium Alloys).

4. Heating Method

- electrically heated or fuel-fired.

5. Heating Elements

- Nichrome Wire/Special Alloy Resistance Heating Wire

6. Quench Media

- Utilizes various quench media such as oil, water, or polymer depending on application requirements.

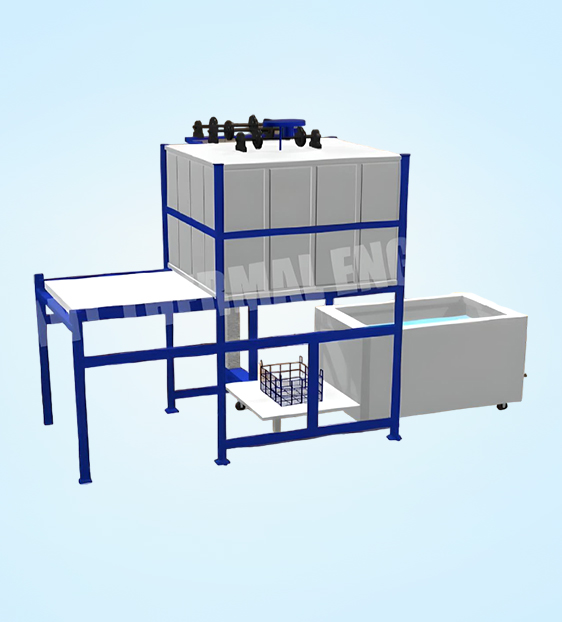

Drop Bottom Quench Furnace - Designed to Meet Heat Treat Requirements

Drop-bottom quench furnaces are specialized industrial heating equipment designed for precise heat treatment processes.

They play a vital role in various industries, including automotive, aerospace, and manufacturing, by improving the mechanical properties and performance of metal components.

If you’re looking for a high-quality quench furnace, look no further than Vibrant Thermal Engineering. We are trusted brands renowned for our unwavering commitment to quality and innovation in industrial furnace solutions. As leading Drop Bottom Quench Furnace Manufacturers in India, we use the finest quality materials to build our products.

Our Quench Furnaces feature double-wall construction, with fiber blankets strategically positioned between the inner and outer walls to ensure superior insulation and minimal heat loss. We provide complete control and instrumentation systems, utilizing PLC-based or hardware-based logic controls to meet diverse operational requirements.

If you’re looking for a high-quality quench furnace, look no further than Vibrant Thermal Engineering. We are trusted brands renowned for our unwavering commitment to quality and innovation in industrial furnace solutions. As leading Drop Bottom Quench Furnace Manufacturers in India, we use the finest quality materials to build our products.

Our Quench Furnaces feature double-wall construction, with fiber blankets strategically positioned between the inner and outer walls to ensure superior insulation and minimal heat loss. We provide complete control and instrumentation systems, utilizing PLC-based or hardware-based logic controls to meet diverse operational requirements.

Features Of Drop Bottom Quench Furnace

01. High capacity

02. Safe operation

03. Energy efficient

04. Easy operation

05. Fast cycle times

06. Rapid quenching

07. Durable construction

08. Minimal maintenance

09. Inert gas atmosphere control

10. Uniform temperature distribution

VIBRANT THERMAL ENGINEERING

We are a renowned furnace technocrat with ISO 9001-2015 furnace manufacturing unit certified by the TUV. A Qualified team of Design, Manufacturing & Site Services to meet customer expectations.

Various Applications Of Drop Bottom Quench Furnace

Processes requiring fast quenching times

Continuous ageing cycles (16-24 hours)

Solution heat treatment of aluminum alloys

Ageing and annealing of metals

Heat-treating components for aerospace and automotive industries

Industrial processes requiring high capacity and fast turnaround

times

times

Applications demanding tight temperature uniformity

Brazing of metals

Heat treatment cycles

Forging aluminum alloys

Look For the Trusted Brands of Drop Bottom Quench Furnace

Whether it's annealing, tempering, or solution heat treating, our Quench Furnaces offer precise control over temperature and atmosphere, enabling superior metallurgical outcomes with minimal energy consumption. Rigorous quality control measures are integrated at every stage of production, from design to assembly, ensuring that each Quench Furnace that bears our name meets the highest standards of excellence.

As one of the leading Drop Bottom Quench Furnace suppliers in India, we take pride in providing comprehensive support to our customers. From installation and commissioning to after-sales service and maintenance, our dedicated team is committed to ensuring the seamless operation of your furnace throughout its lifecycle.

As one of the leading Drop Bottom Quench Furnace suppliers in India, we take pride in providing comprehensive support to our customers. From installation and commissioning to after-sales service and maintenance, our dedicated team is committed to ensuring the seamless operation of your furnace throughout its lifecycle.

Call Us Now

(+91) 94-440-63455